Furniture `design Project: Adirondack Chair

with Master Furniture Designer - Andrew Lee

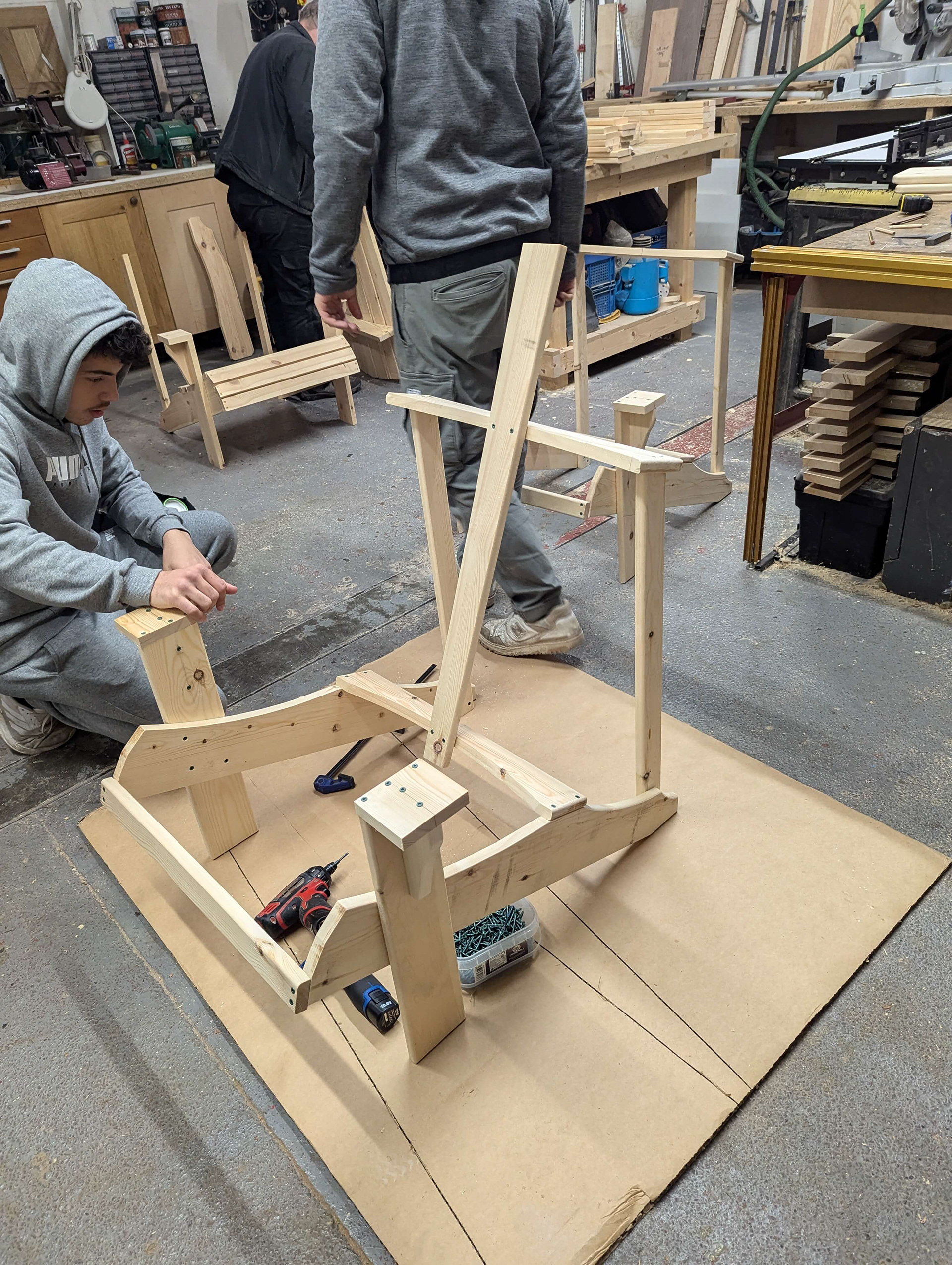

The Build

1. Identify Wood

Used large boards from corner of workshop

2. Cut boards to length with Mitre Saw

Used jig to identify the length of the necessary parts

Marked lengths on with pen and a tri-square

Cut with a mitre saw leaving some space to the line considering the kerf of the saw

3. Draw on boards with jig

Drew around the jigs on the boards

Fitted two back slats on each part to maximise use of material

2 x big back legs

2 x front legs

Top and bottom back support sections

4. Use bandsaw to cut close to jig line

Used the bandsaw to cut the curves in the large back leg parts

Used bandsaw to cut the back slats down middle line

Used bandsaw to cut curved back sections

5. Use router to smooth edges / curve edges

Smoothed edges of every part

Ensured that the useful face is considered so only required ones are curved

6. Cut slats using table saw

Cut larger parts of wood to correct size using mitre saw

3 seat slats per cut

Use the table saw to cut the individual slats

Ensure hand part is used to be safe - keep fingers away from saw

7. Use belt sander to create curved edge pieces

Cut small under arms section with mitre saw and bandsaw

Used belt sander to create smooth curves equal on both sides

8. Use Orbital sander to smooth all surfaces

9. Use planer to cut planks to correct depth

10. Use table saw to cut long back structural beams and plane them

11. Begin assembly

Used jig to mark out where the holes will be and ensure base parts and front legs were at correct angle

Drilled holes using hand drill

Inserted countersunk screws using hand drill

Attached lower back slat support onto the bottom legs - ensure distance apart was correct

Had to ensure they didn’t go too deep so that they don’t show through on the other side

Connected back beams and top back slat support ensuring angles were correct

Spirit level used to ensure flatness throughout

12. Use glue to secure one part of support

Marked holes using jig and glued to the top of the handle parts before then drilling through and adding screw

13. Secure centre board

Drill holes in the centre board and into the lower back slat support

Insert screws

Repeat for upper back slat support

14. Place and secure other boards around it

Repeated process for all the other back slats ensuring they are spaced equally from the centre and that the screws are along the same line

This was two-person job - one person hold it other person drill and screw

15. Secure seat slats

Finally secured seat slats aiming to place them evenly apart

Remembering some at the front were slightly larger

Large section done was right at the front where we wanted to minimise the angle to make it more comfortable

Planed down the front bit to ensure it was comfortable with hand planar

16. Attach arms

Marked out holes and attached the big arms both on the flat section at front and at the back for stability

Ensured it was symmetrical

17. Cutting the shape

Marked the top section in desired shape

Cut the shape of the top section using jig saw

18. Selecting stain Finish

Explored decking oil to cover the individual bits of wood to ensure protection from the elements when used outside - to be completed at a later date

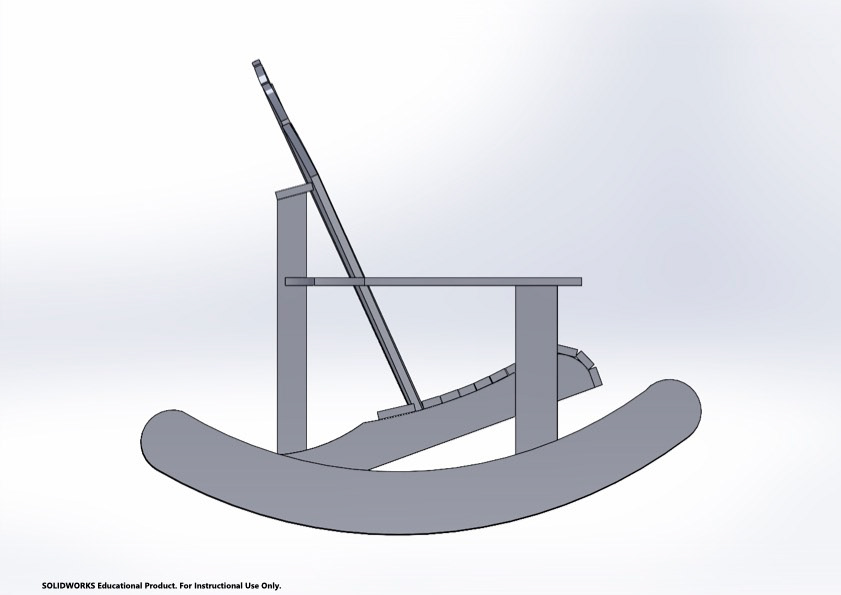

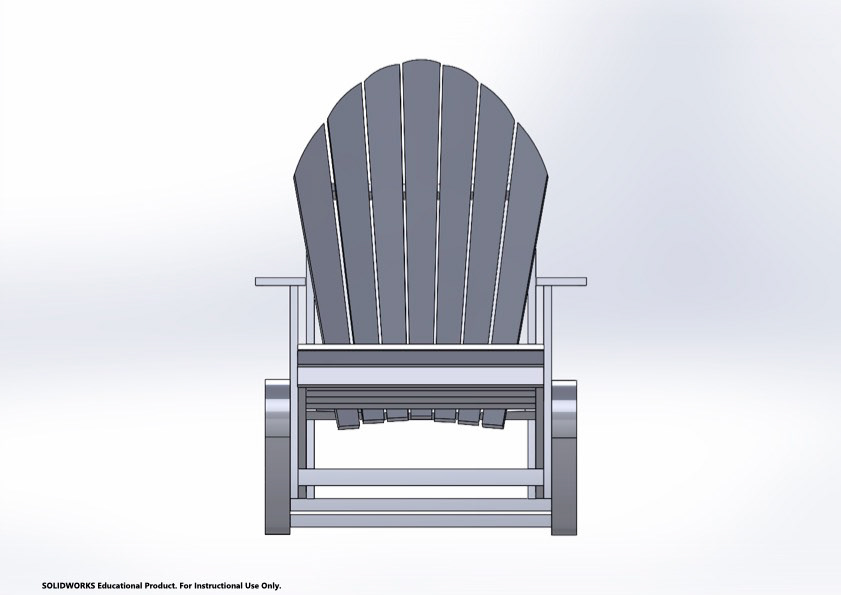

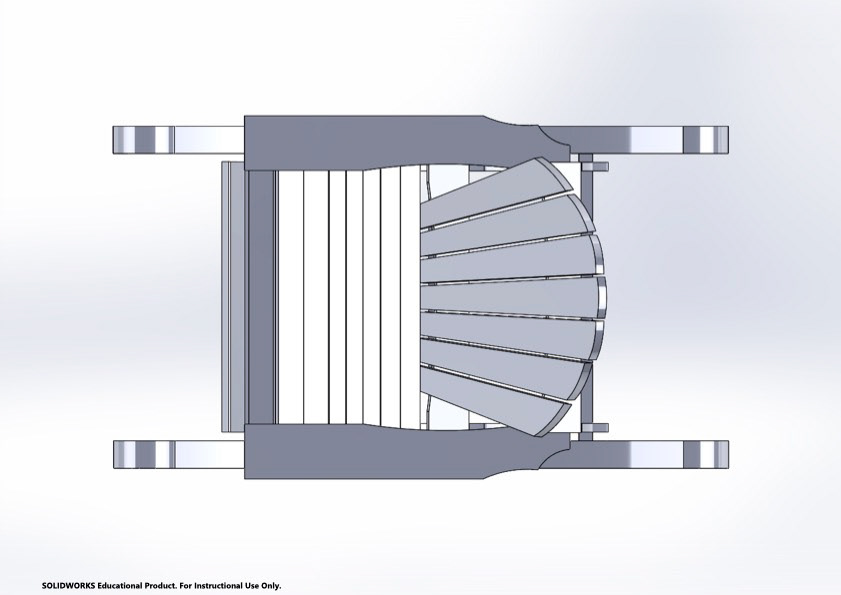

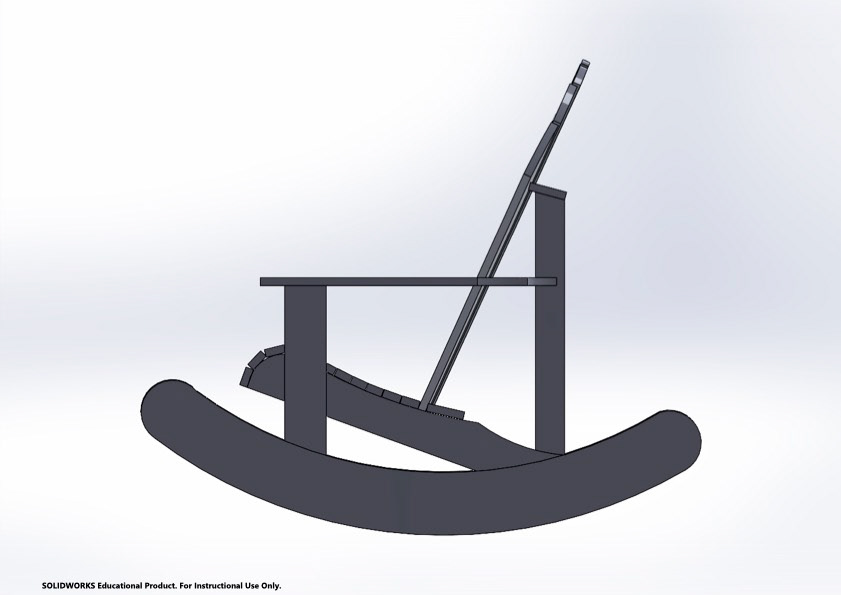

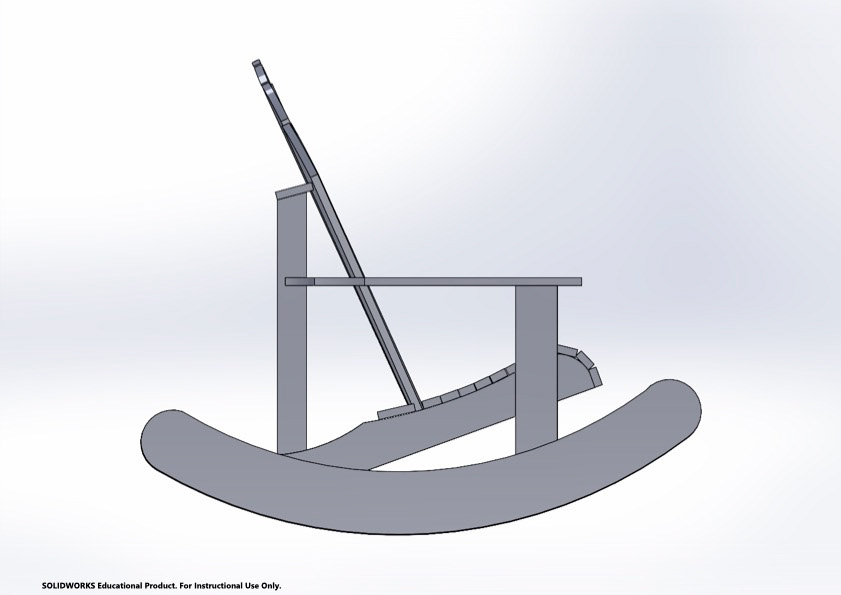

Chair Version ii: Adapting it to a rocking chair

work in progress

3D Images in SolidWorks created by Tracey Kumi

Design Specification

Aesthetics:

Adirondack-style garden rocking chair

Show craftsmanship and beauty of materials

Spacious and comfortable

Wide arms for putting cups and small items on

Soothing rocking motion

Easy to stand up from sitting

Costs:

Cost of Pinewood

Cost of screws bolts nuts

Time taking to make

Workshop time

Customer:

Mother convalescing from treatments

For sun garden/day-chair in bedroom

Relaxing, socialising, reading and sewing

Good angle for sitting posture and use of back rest

Aesthetically pleasing, showing craftsmanship skills, quality build and natural materials

Environmental:

Using non-permanent fixtures so can be undone and cycle again

Using sustainably sourced pine wood – native to UK (low carbon footprint)

Environmentally friendly and non-toxic stains

Use of standard size nuts and screws

Size:

Large and spacious for all sizes (of family members and guests)

Smooth movement/tilt in rocking chair action to facility ease of standing up from same position

Safety:

Must be strong enough to hold a person's weight

Ergonomic design - for back support

No moving parts that could snag or catch fingers, etc

No use of toxic substances or materials (stains/glued )

Function:

Garden chair for lounging outside but also used for day room chair

Arms wide enough to hold cup, small plate, books and other small items

Smooth rocking motion

Easy sitting to standing action

Material:

Pinewood - UK sourced

Steel ( screws, nuts & bolts)

Non-Toxic glue for small piece supporting frame

Non-Toxic stain to protect chair when outside

Manufactured using power tools, bandsaw, mitre sore, router, planer, orbital drill.